Plates

Pro6 Repro uses the most advanced equipment to cover all different type of plate-making processes. This way we can produce our printing plates in the quality our customer desires.

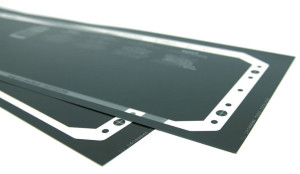

Laser engraved printing plates

To produce our plates, we use the latest and most advanced techniques in the field of plate-making. The quality of laser-engraved plates has set a new standard in the Dry Offset and Flexo industry. Today, high quality images can be so effortlessly printed with laser-engraved plates that over the last few years, laser-engraving has successfully competed with the quality of in-mould labeling. Also the costs involved are several times lower than those associated with in-mould labeling. So the choice is a very easy one to make.

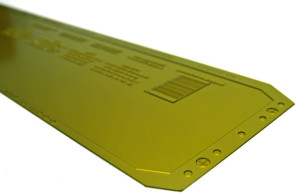

CTP UV-laser exposed printing plates

Pro6 Repro has recently invested in a new CTP system from Luscher. This machine makes use of a new technology called X!Direct. This special developped software makes it possible to directly expose the plates with the help of a UV-laser. The main benefits of UV direct imaging for Dry Offset and Flexo applications is the elimination of the masking technology and its associated costs, process steps and difficulties such as contamination of wash out chemicals. Purpose of the software X!Direct,

UV laser light is highly collimated, penetrating straight and deeply into polymer materials to crosslink them directly. This leads to sharp deep shoulders and open reverses for relief printing forms. For small positive elements such as fine lines, text and highlights, there is however the need to support these with optimal shoulders and this is the main purpose of the software development. This is the only CTP system in the world using this new state of the art technology.

Pro6 Repro is proud to be the first in the world to use this new technology and present its customers with the highest quality possible in CTP UV-laser exposed plate-making.

Conventional printing plates

Besides laser engraving and our new CTP system, we still use our conventional procedures, which involves exposing the plates via film. By using our own special exposing technique, we are able to produce a very sharp image on the plates. This way we can guarantee the highest quality possible using conventional plate-making.

If you would like to receive more information, please do not hesitate to contact us.